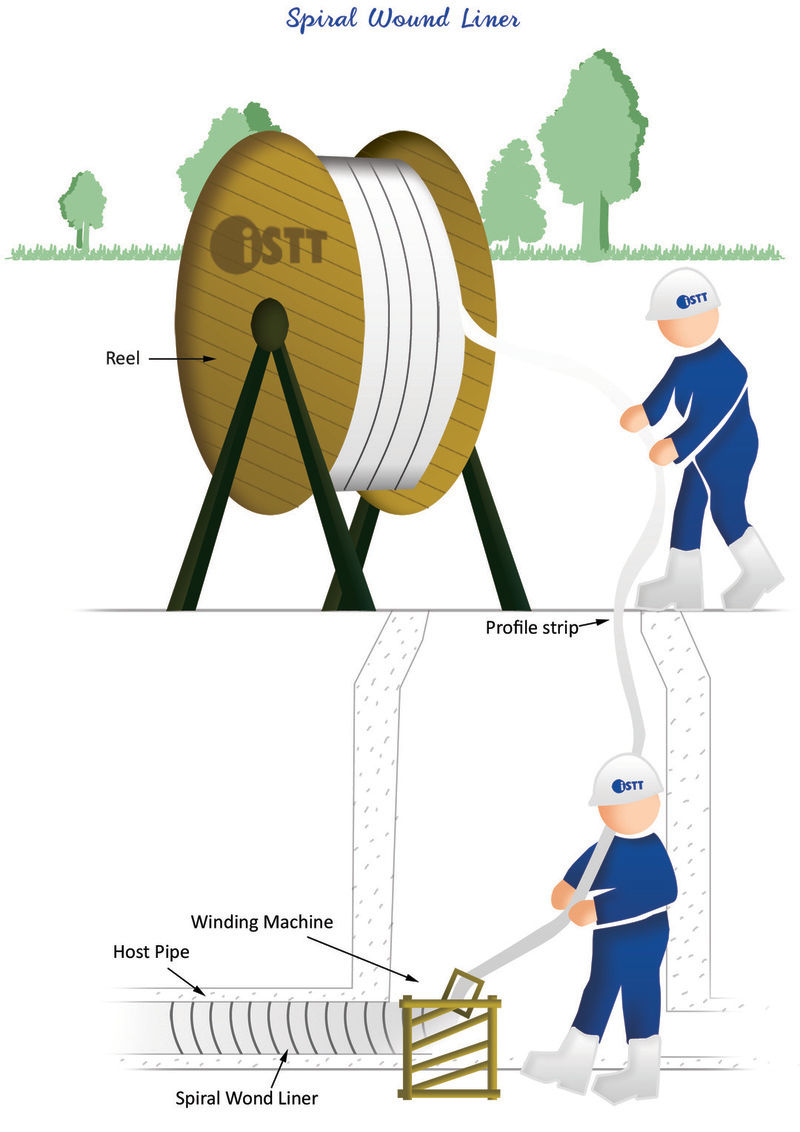

Spiral wound liners can be used to rehabilitate gravity pipeline applications such as storm sewers, sanitary sewers, conduits, culverts and process pipes. Spiral wound linings comprise several allied but distinct approaches to creating a liner pipe or a structural lining within an existing host pipe or tunnel. The configuration of spiral wound liners often allows installation of the liner without the use of over pumping. The originally developed spiral wound approach used an extruded PVC strip that could be spirally wound with the adjacent edges of the strip able to lock together so that the spiral wound strips form a water-tight continuous pipe. T-shaped ribs on the extruded strip provide stiffness and strength to the wall of the pipe so that it can potentially function as a fully structural lining. The liner is installed in-situ in the host pipe through a manhole or insertion pit. Profile strips of PVC, steel reinforced PVC or HDPE located on spools above ground are fed to a winding machine. The rotational action advances the liner through the host pipe. In smaller diameter pipes, the liner can be expanded by the winding machine to form a tight fit with the host pipe.

Alternatively, a fixed diameter, field-fabricated liner can be installed, and the annular space between the host pipe and liner grouted. The winding machine can remain stationary at the inserting pit in line with the host pipe, or for larger diameter circular or non-circular applications, the machine can travel along the host pipe. The traveling machine installs the spiral wound liner in contact with the host pipe forming a close-fit liner that generally conforms to the profile of the host pipe. Or, as above, the liner may be installed with a fixed dimension and the annular space between the spiral wound liner and host pipe grouted. Laterals are located by measurement and reinstated after lining. Grouting of the annular space is generally preferred to lock the liner in place, effectively transferring external loads from the existing pipe onto the liner and to mobilize the support of the existing pipe to achieve the full potential of the liner to carry external loads. The installation results in a smooth interior wall of the liner pipe and with the ribs of the liner strips facing the inner wall of the host pipe. A spiral annular gap would remain between the liner and the host pipe unless this gap was grouted as discussed above.

The spiral wound approach also has been used to allow similar extrusions to be wound together to provide a lining for large pipes or tunnels and for non-circular cross sections. In this approach, a traveling frame within the large pipe or tunnel is used to form the shape of the wound lining. This approach inevitably leaves a significant gap between the wound liner and the wall of the pipe/tunnel. This annular space is grouted with a structural grout and the ribs of the extrusion lock the wound liner and the grout together to form a fully structural liner with a tight fit to the existing structure. In order to provide additional strength and stiffness to the wound plastic liner in larger diameter applications, metal strips are incorporated into the liner strips as they are wound.