Polymeric coatings and liners (notably epoxy and polyurethane (PU)) are used to provide corrosion protection in small diameter metallic pipelines and corrosion protection and semi-structural rehabilitation and leak protection in man-entry pipes, tunnels and manholes. As with cement mortar liners, epoxy and polyurethane coatings require that the host pipe be thoroughly cleaned of hard deposits, nodules, scale, corrosion and other debris and be substantially dry prior to application of the coating to ensure good adhesion between the liner and the pipe wall (see Cement Mortar Lining for discussion of cleaning technologies). Epoxy and polyurethane spray-on liners, like cement mortar, protect the host pipe against corrosion and improve the flow characteristics of the host pipe. A thicker coating of polyurethane can be applied to the pipe to provide a measure of semi-structural integrity and leak protection. Epoxy and polyurethane coatings inhibit corrosion by forming an impermeable barrier between the host pipe and the flow stream of the pipe.

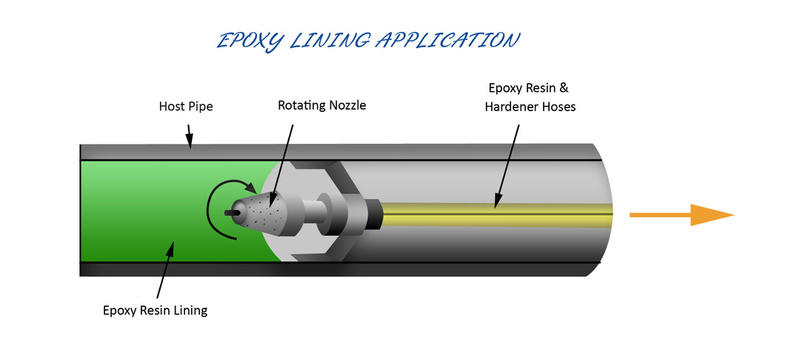

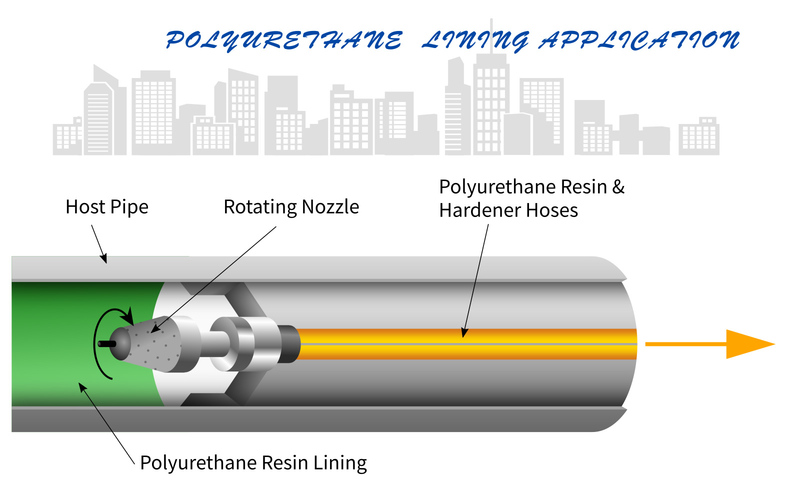

In small diameter (non man-entry) pressure pipes, a thin layer (1-1.5mm) of epoxy or polyurethane is sprayed on using a high speed rotating nozzle. In most cases the resin and hardener are fed through separate hoses and combined by a static mixer just behind the spray nozzle. The thickness of the coating is controlled by the flow rate and forward speed of the spay machine. Unlike cement mortar lining, the resin is not smoothed or trowelled after spraying. Epoxy spray liners cure in approximately 16 hours, much quicker than cement mortar, while polyurethane spray liners cure in about 2 hours. Both liners are thinner than cement mortar liners. However, these liners are more expensive and require careful quality control during application and curing to ensure that the lining is free of defects that would allow corrosion to restart. Epoxy and polyurethane-based coatings are also used for rehabilitation and corrosion protection of larger man-entry tunnels, pipes, manholes and other water and wastewater structures. The coatings are applied by hand or by spray. Thicker applications of polymer coatings may offer structural benefit and leak protection.

Polymeric Coating - Lining (epoxy and polyurethane PU)![]() Descargar / Download

Descargar / Download