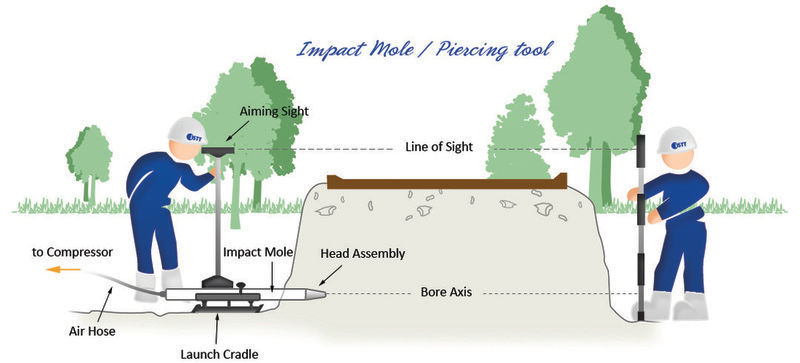

The impact mole or piercing tool is one of the oldest and simplest of the trenchless technologies. It is ideally suited for installation of small diameter pipes in compressible soils over short distances. Under suitable conditions the installation of a product using an impact mole is simple and straightforward. The impact mole is positioned on a skid or cradle at the desired line and grade determined by a sighting level positioned on the mole. Once the mole is in the desired position, the compressor is activated advancing the mole through the hammering action of the reciprocating head. The chisel-tip head creates a bore hole. The long body length of the mole helps the mole hold line and level as it advances through the bore hole although deviations are possible due to uneven ground conditions or obstructions. Marking on the air hose allows the operator to track the distance traveled by the mole as it advances through the ground. Once a bore hole has been completed, the product pipe is pulled in as the mole is extracted. A bore hole is typically 15-25 percent bigger than the product pipe.

Some newer impact moles are steerable. The method of steering is similar to that used in pilot bores and directional drilling. A steerable mole has a slant face rather than a chisel-tip face. The direction of the mole is altered through the positioning of the slant face head. The operator steers the mole by rotating the face in the desired direction. A sonde located in a transmitter-housing near the front of the mole allows the mole to be tracked using a walkover tracking system.

Impact Moling![]() Descargar / Download

Descargar / Download